Sewerage - Water Treatment Plants

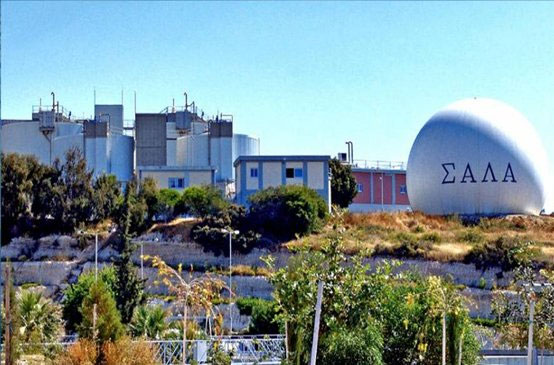

Wastewater Treatment and Recycled Water Production Plant in Moni

The Wastewater Treatment and Recycled Water Production Plant in Moni commenced operations in 1995. The Plant has the capacity to receive up to forty thousand cubic metres of liquid waste per day and can process approximately sixteen thousand kilograms of biological load daily. It produces high-quality treated water.

The tertiary treated water is suitable for use in agriculture and industry and is delivered to the Water Development Department, which is responsible for its distribution.

The sewerage system plays a crucial role in water conservation for agricultural use, as the disinfected water at the end of the tertiary treatment process is suitable for both agricultural and other purposes. By reusing treated water, we save water from dams and underground reserves.

Currently, the plant produces approximately ten million cubic metres of treated water per year. This amount is expected to increase as new areas are becoming connected.

Utilisation of Renewable Energy Sources – Biogas

In addition to water and biosludge reuse, biogas is also produced and used for the cogeneration of electricity and heat, thereby contributing to energy conservation.

Since 1 September 2008, the Board has installed and operated two biogas generators, each with a capacity of three hundred and eleven kilowatts, for the cogeneration of electricity and heat.

The biogas, derived from the anaerobic digestion of biosludge, is collected in a gas holder with a capacity of two thousand cubic metres. The biogas produced in the sludge digesters is used as a renewable energy source—"green" energy that is environmentally friendly—and is utilised to operate electricity generators. The heat produced by the generators is used to heat the digesters, while the generated electricity, currently around five thousand kilowatt-hours per day, is used for the operation of the Wastewater Treatment Plant in Moni, reducing daily electricity consumption from the Electricity Authority by approximately 35% to 40%.

At the same time, the thermal energy produced, which currently amounts to around four kilowatt-hours per day, is used to heat the sludge as an alternative heat source. Due to the controlled production of biogas, pollutant emission levels remain very low.

This approach achieves significant energy savings while reducing additional environmental impact. Based on the plant's current operational levels, the electricity generated from the biogas generators amounts to approximately 4.5 thousand kilowatt-hours per day, with production expected to increase to 5 thousand kilowatt-hours per day as the networks expand.

Furthermore, the Board secured a subsidy for the initial capital expenditure from the Renewable Energy Grants Service of the Ministry of Commerce, Industry, and Tourism. The investment cost was approximately two million euros, while the subsidy amounted to three hundred and twenty thousand euros.

Biosludge

The treated sludge (biomass) produced from wastewater treatment is suitable for use in agriculture, forestry, gardening, landscaping, and mining (for soil improvement to restore vegetation and revitalise green areas).

Wastewater Biological Treatment and Recycled Water Production Plant of Western Limassol

The Plant is located on agricultural land within the administrative boundaries of Kato Polemidia Municipality, within the territory of the British Bases. It is situated away from residential areas and adjacent to the Stormwater Retention Lake. The facility is approximately 500 metres from Limassol’s First Industrial Zone and about 1,200 metres from the nearest residential zone of Kato Polemidia Municipality.

The contract for its construction was signed on 30 November 2018 with the consortium "Kruger A/S – Cybarco Limited JV." The project commenced in January 2019, and construction works were completed in September 2022. The project was included in the European co-financed projects of the 2014–2020 Programming Period under the European Union’s Cohesion Fund. The project's total cost amounted to approximately 30 million euros and was co-financed by the Republic of Cyprus and SBLA.

On 7 March 2020, the foundation stone ceremony for the Western Limassol Recycled Water Production Plant was held. The foundation stone was laid by the former President of the Republic of Cyprus, Mr Nicos Anastasiades.

The Plant, with a capacity of thirteen thousand cubic metres per day, serves the areas of Polemidia, Zakaki, Ayios Spyridonas, as well as other regions in the broader Western Limassol area. It also provides services to the Limassol General Hospital, the New Limassol Port, Limassol’s First Industrial Zone, and major commercial developments such as the “City of Dreams Mediterranean” casino and “MyMall”. In the future, the plant has the capacity to serve 65,000 residents.

This project is one of the most significant infrastructure developments undertaken in the city and district of Limassol. It is a high-tech facility of great environmental importance. During its design phase, special attention was given to ensuring minimal to zero levels of noise and odours, while it is based on membrane technology for tertiary treatment.

On 4 November 2023, the Official Inauguration Ceremony of the Western Limassol Wastewater Treatment and Recycled Water Production Plant of SALA was conducted by the President of the Republic, Mr Nicos Christodoulides.

Building infrastructure

Treatment Stages

Wastewater Inflow (K.01)

Wastewater enters the Plant through gravity from higher areas and via pumping from lower areas through the SBLA Z Pumping Station, located in the Lady’s Mile area.

Pre-Treatment (K.02)

Upon entering the Plant, the wastewater undergoes preliminary treatment through two coarse screens with a permeability of <6mm and three fine screens with a permeability of <1.5mm. The screened waste is compressed and placed into sealed transport containers, which are sent to licensed disposal facilities. The wastewater then flows by gravity into two elongated grease, oil, and grit removal tanks, which are enclosed to prevent the release of odours. The floating fats and oils are collected and directed to the digester (K.12).

Subsequently, sand, gravel, and other heavier-than-water solid particles that settle are pumped into a grit collection channel, separated from the liquid phase, and transported in a sealed truck to a licensed treatment facility.

Primary Sedimentation (K.03)

The wastewater flows by gravity from pre-treatment into two enclosed elongated sedimentation tanks, preventing odour leakage. At this stage, organic load is reduced by 20-40%, and suspended solids by 40-60%.

Biological Treatment (K.05)

The wastewater then overflows into two circular aeration tanks via a separation chamber, where two sludge recirculation lines also merge. During biological treatment, wastewater and microorganisms mix and remain in contact within the tanks, with controlled aeration and mixing rates. The decomposition of organic load occurs under controlled temperature, oxygen levels, and retention time. The tanks operate in cycles of aerobic (presence of oxygen - nitrification) and anoxic conditions (absence of oxygen - denitrification).

Membrane Bioreactor Filtration (K.07)

From the aeration tanks, the mixture of water and biological sludge flows by gravity into a separation chamber before entering filtration tanks, where it passes through membrane bioreactors. There are three membrane filtration lines within a closed system to prevent odour leakage. These lines serve as the final filtration step for producing tertiary treated water.

UV Disinfection (K.09)

The tertiary-treated water from the membranes is disinfected using ultraviolet radiation, ensuring the complete inactivation of any remaining microorganisms.

Irrigation and Emergency Pumping Station (K.23)

After UV disinfection, the tertiary-treated water is directed to the reservoir of the Water Development Department (WDD), which is responsible for its distribution for agricultural irrigation and groundwater recharge.

Sludge Treatment (K.10, K.11, K.12)

The generated sludge undergoes thickening, anaerobic digestion, and dewatering. The dewatered sludge, with a minimum moisture content of 25%, is stored in a 70m³ storage area and transported in a sealed truck to a licensed processing unit.

Biogas Production (K.13, K.15)

Biogas is produced through anaerobic digestion and is supplied to cogeneration units for electricity and heat production. The generated energy meets the plant’s operational needs, while the heat is utilised for sludge digestion.

Chemical Storage Facility (K.16)

This facility stores iron chloride, which is used for phosphorus reduction when necessary.

Odour Control System (K.17)

Odour control and capture systems are installed at all treatment stages where odour emissions may occur, ensuring minimal release into the environment.

Renewable Energy Sources

The plant features photovoltaic panels with a capacity of 200kW, with provisions for an additional 100kW. Furthermore, biogas is utilised for electricity and heat generation, as mentioned above.

Electrical Equipment Building (K.20)

This building houses electronic control panels, a backup generator, and other electrical equipment.

Administration Building (K.19)

The Administration Building accommodates staff offices and the control room, where the plant's entire operation is monitored. The facility includes an advanced Supervisory Control and Data Acquisition (SCADA) system, noise control systems, a state-of-the-art laboratory, and other cutting-edge technologies.

The Western Limassol Wastewater Treatment and Recycled Water Production Plant is one of the city’s most significant infrastructure projects. It undeniably enhances the quality of life, supports economic activity, and promotes environmental protection.